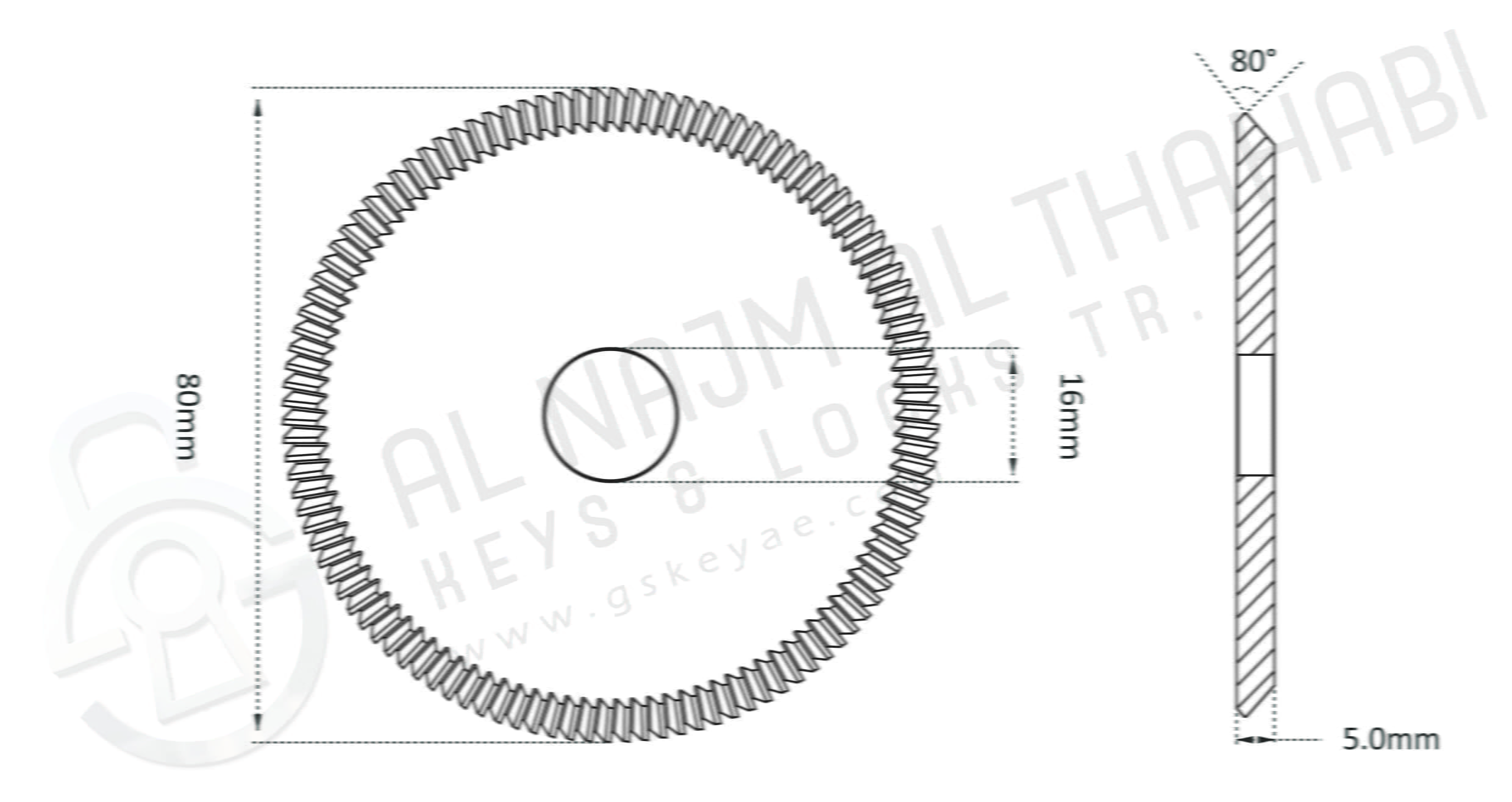

Angle Milling Cutter Carbide Material Φ80X5XΦ16X80°-0.5 2028 For ILCO SILCA, KEYLINE Dezmo:

Manufacturer: Al Najm Al Thahabi

GS Ref. : WP032

Material: Carbide

Compatible with machine: ILCO KD50A, KD71A, KD50C; SILCA Bravo II, Bravo III,Bravo III w/EZ Jaw KEYLINE Dezmo

D[mm]: 80

d[mm]: 16

Thick[mm]: 5

FOR MACHINE:

Compatible with ILCO KD50A, KD71A, KD50C; SILCA Bravo II, Bravo III,Bravo III w/EZ Jaw KEYLINE Dezmo

Features:

1.Material: Solid carbide, the hardness reaches HRA92.5 or above, quite high hardness. The cutting edge is sharp .It does not need to change the machine and also can process copper keys and iron keys on same key machine. No longer needs to change the cutter.greatly save your precious time. Especially suitable for processing cross iron key, can process 500-800 pieces of iron cruciform keys and about 4 times than the welded carbide cutter.

2.Production process: After 11 grinding processes, CNC precision grinding process, the cutting edge is extremely sharp. It can be called dragon cutter. The major breakthrough is the use of reinforced cutter tip, completely overcome the problem of broken on the tip of teeth.

3.In view of the characteristics of carbide brittleness, Al Najm Al Thahabi invented a unique grinding process, strengthen the cutting edge and improve the rigidity of the tip of cutter. It’s very good to overcome the problem of broken teeth.

4.Double-sided teeth, both sides can be cut and both sides can duplicate the key. Twice life as normal cutter.

5.Dense tooth type, scissor tooth, light cutting, less wear, super durable. Iron key and copper key can be processed.

READ BEFORE USING:

Carbide material is with high hardness and brittle, in the use of the process should pay attention to feed and feed speed to slow, to prevent broken teeth.

The cutter should rotates completely before cutting the key.

Reviews

Clear filtersThere are no reviews yet.